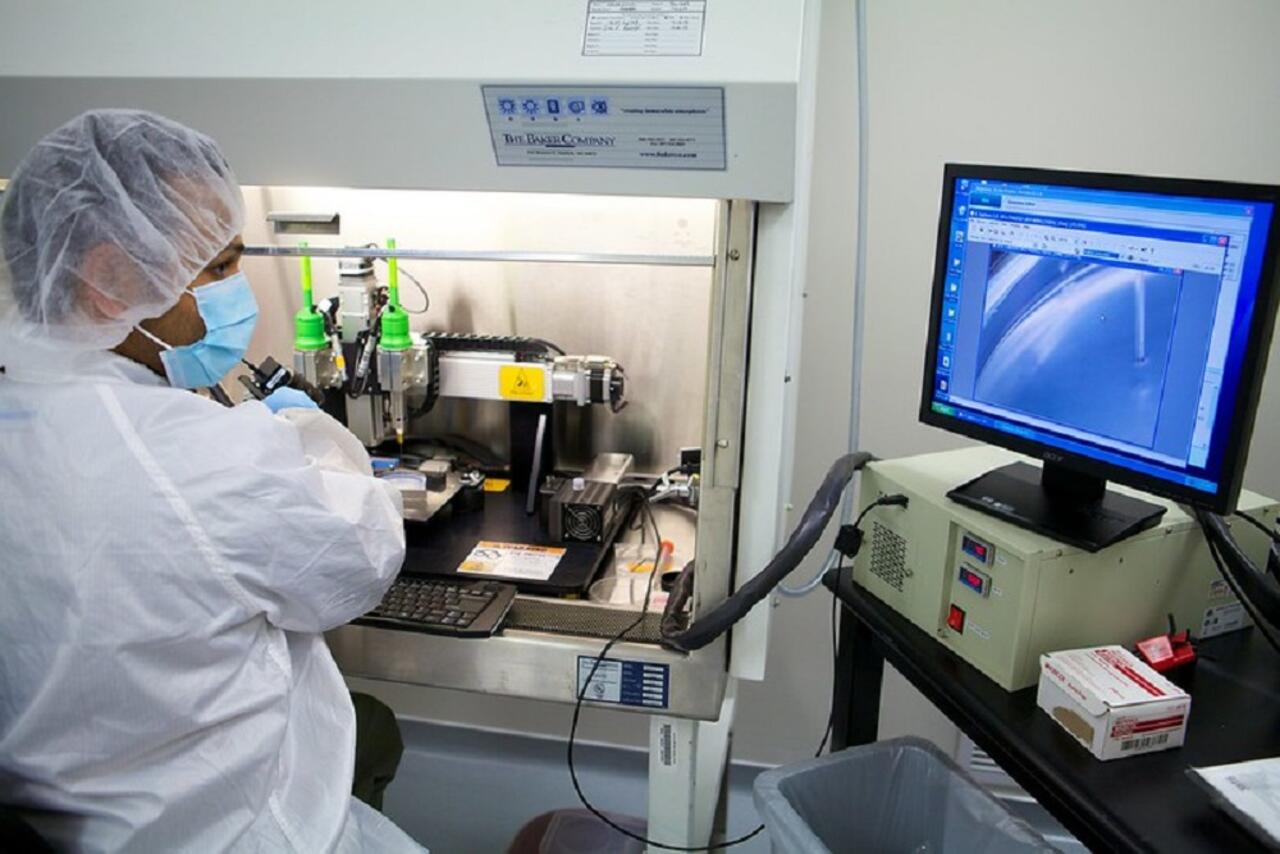

Flanders pioneers in the 3D bioprinting of human tissues

A breakthrough

For years, Flanders has been a pioneer in the field of 3D printing technology with applications in many sectors. The latest innovative project by Xpect-INX is a breakthrough in the medical 3D bioprinting industry. The UGent spin-off developed biocompatible materials, called ‘bio-inks’, that bear a strong resemblance to the natural human cell environment, making it possible to print body tissues.

"Developing a way to 3D-print cells and tissues has been a challenging task," says Jasper van Hoorick, researcher at Ghent University and cofounder of Xpect-INX, “because 3D printed cells must be able to grow and function like normal human cells and interact with existing cells until the body can fully integrate them.”

Major opportunities

Today, common medical interventions such as breast reconstructions, heart valve replacements and meniscus transplants are often not without complications. Xpect’s bio-inks offer a sustainable and patient-specific solution, since damaged tissues could be replaced by 3D-printed endogenous cells. In time, it will even be possible to print entire organs, responding to the pressing shortage of donor organs.

"Our technology also creates possibilities for clinical studies,” comments Van Hoorick. “We can grow cells or mini organs on which to test new medicines. In this way, we can significantly reduce or even completely stop animal testing.”

All-in-one service

To print using bio-inks, Xpect-INX has closed a first distribution contract with Regemat 3D, an international bioprinting company headquartered in Spain. "Through this collaboration, we can not only offer customers the right printer for their needs, but also immediately supply the right materials, which drastically shortens their research process," says Zukhra Battalova, business developer at Regemat 3D.